A concept with roots in science fantasy has been put into practice as a mechanical engineering capstone project by six students at Northern Arizona University.

The atmospheric water generation device designed and built by Travis Butterly, Andy McPhail, Nathan Allred, Nathan Ogbasellasie, Eassa Alowis and Adnan Alhashim not only generates water from air, but also collects data used to determine the feasibility of water generation in an arid climate.

When the project was first proposed, “All I could think about was Star Wars,” McPhail said, recalling a scene involving moisture farming. “That’s the nerdy reason I picked this one.”

Despite that projection into the future, atmospheric water vapor extraction is not a new concept. Industrial-sized versions of such machines have been used for disaster relief in places where water is not readily available. But technological advances within the past couple of years make the process more viable for personal use, and that’s the interest of Chris Allender, the local client with whom the students are collaborating.

Engineering capstone projects at NAU involve design and manufacturing over a student’s senior year. Teams of students work with a client to produce a design that could achieve practical application.

“Chris wants to know if it’s feasible to create a commercialized product for dry areas like Flagstaff,” McPhail said.

The team determined it needed to design a refrigeration system that would cool down ambient air 15 degrees. This air cooling would create condensation through a system of channels that drip into the bottom of the system, where water could later be extracted.

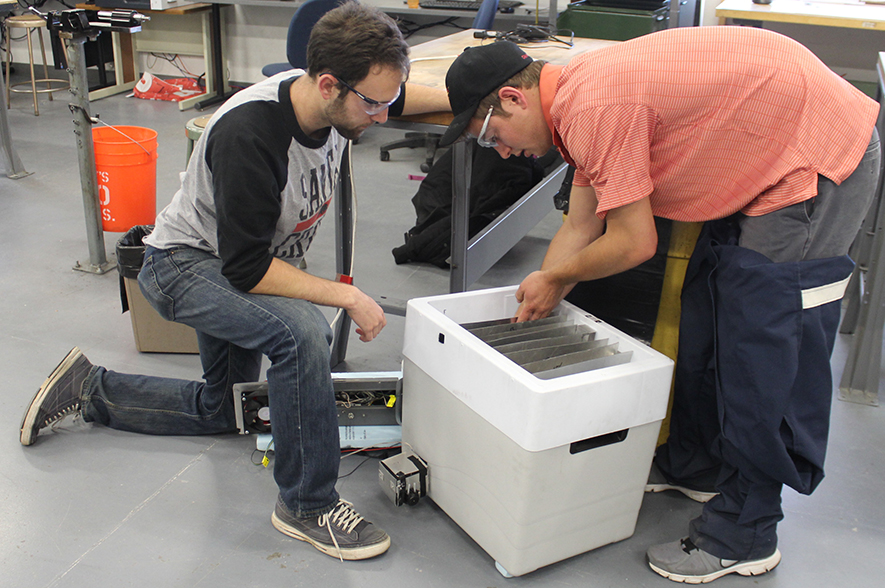

During the manufacturing stage, the students worked to build the body of the machine and create the electronic devices to get it working and logging data.

The group is now in the final stages of creating the extractor.

“We’re just in the optimization process right now,” Butterly said. “It is collecting water, but the amount is not what we were hoping for, so we still need to make some tweaks to it.”

McPhail said the initial goal was two liters a day, but “two liters around here probably isn’t going to happen.”

Butterly and McPhail have ideas for how to increase the amount of water generated and they feel optimistic about the success of their product in more humid environments.

“That’s why we wanted to make it portable, so we can travel to different levels of humidity and test it out,” Butterly said.

Collaborating with a client has given the students perspective on what industry experience will be like once they graduate.

“It definitely is preparing us for the future,” Butterly said. “Our professor has given us deadlines we sometimes have had to go above and beyond to meet which is realistic to expect in the future.”