Not many people in the world can say that something they built is orbiting Mars—especially not college students. Soon, a cross-disciplinary team of about 35 NAU students—most studying planetary science, astronomy, mechanical engineering or electrical engineering—led by faculty members at NAU will be able to claim that accomplishment. The team’s VISIONS (VISible and Infrared ObservatioN System) camera is scheduled to launch as part of NASA’s EscaPADE mission this fall.

A camera with something to prove

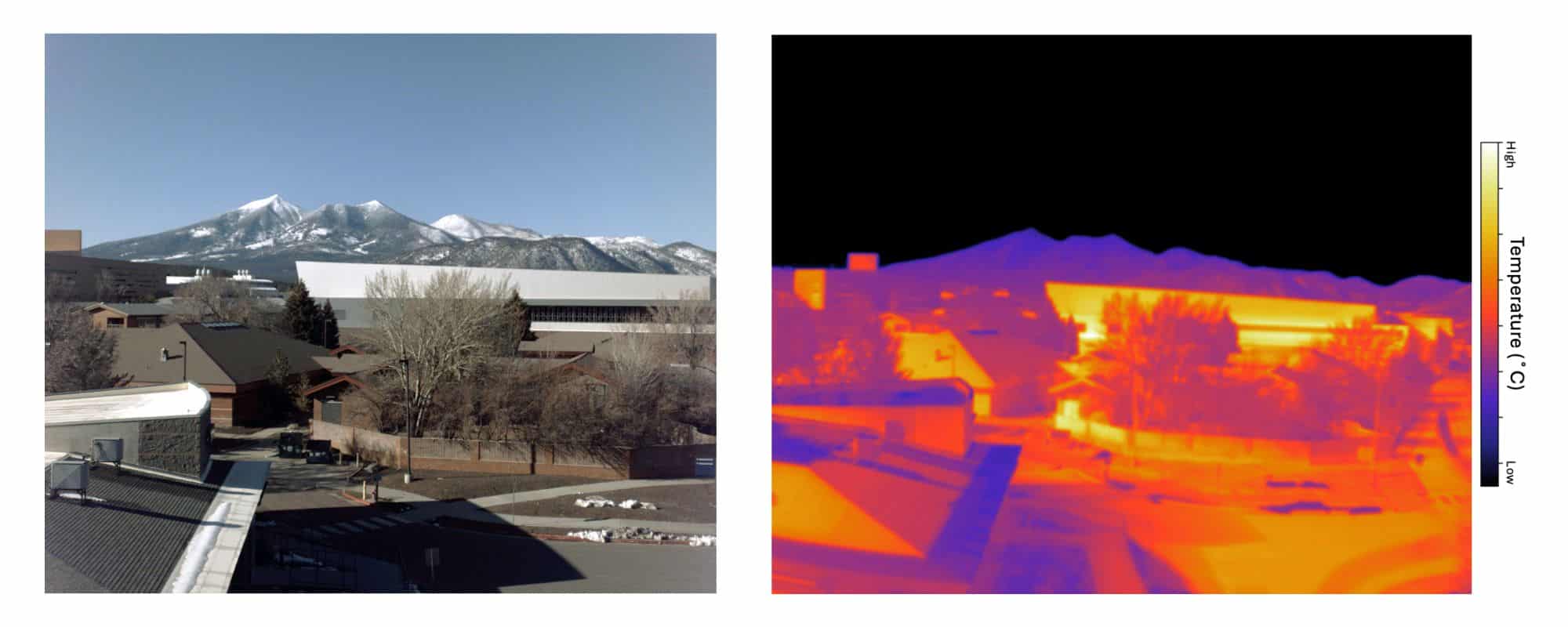

NAU’s VISIONS is a dual wavelength camera that captures images in both visible and infrared wavelength ranges simultaneously, providing more information than either alone.

The VISIONS instrument will help illuminate the composition, physical makeup and climate of the planet at which it is pointed—in this case, Mars. Unlike most other cameras sent on similar missions, which capture images only tens of kilometers wide, VISIONS was designed to capture the whole planet in one frame in both wavelength ranges, making it possible to study things like seasonal changes in the size of the polar caps. Although it’s not guaranteed, the team is also hoping VISIONS will capture images of Mars’ aurorae.

What really sets VISIONS apart is the approach used to design and fabricate it. This low-budget camera is built largely from carefully selected commercially available components—such as sensors and optics—instead of more expensive custom-made versions of these items standard in the spaceflight industry. It also includes electronics provided by Lucint Systems, Inc. VISIONS is something of a technical demonstration, a quest to prove that a low-budget, scientific-grade camera with industrial-grade parts can be viable for spaceflight use, paving the way for future developments and applications.

The EscaPADE mission is part of NASA’s Small Innovative Missions for Planetary Exploration (SIMPLEx) program. The mission’s goal is to study Mars’ unique hybrid magnetosphere. Thanks to cooperation from Robert Lillis, EscaPADE’s principal investigator, and Rocket Lab, the company supplying EscaPADE’s twin Explorer spacecraft, two VISIONS cameras have been given the opportunity to hitch a ride on this interplanetary mission.

Lillis said including the VISIONS cameras on the mission is a win-win-win for those involved, “ESCAPADE gets a real chance to characterize Mars’ green oxygen aurora for the first time, NAU students get invaluable spaceflight hardware experience and the whole scientific community will see what can be accomplished by a dedicated team at low cost.”

Rocket Lab’s CEO and founder Peter Beck also expressed excitement about the student contributions to this important and ambitious mission.

“We are eagerly following the progress of VISIONS and look forward to seeing Mars in a new light thanks to the efforts of these students.

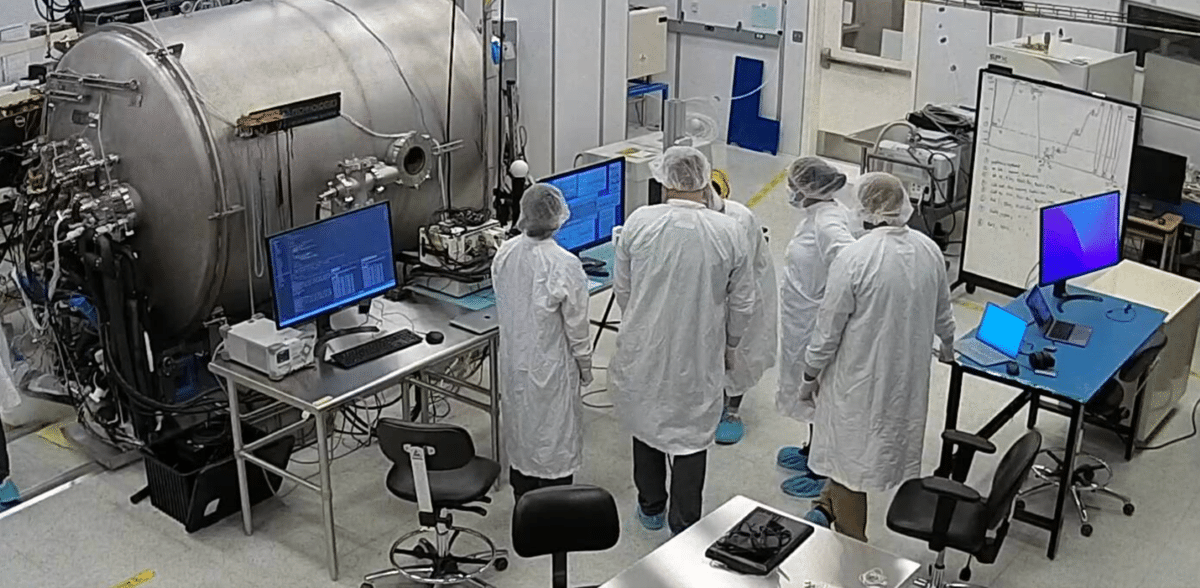

In order to qualify for this unique opportunity, VISIONS had to meet NASA’s rigorous requirements for hardware included on spaceflights, proving that it can withstand and remain functional through conditions it might experience during launch, travel or orbit. Because of this, the camera can survive in temperatures as low as negative 20 degrees Celsius (negative 4 degrees Fahrenheit) and as high as 50 degrees Celsius (122 degrees Fahrenheit), and it can remain operational between negative 10 degrees and 40 degrees Celsius (between 14 degrees and 104 degrees Fahrenheit, respectively). It was constructed and tested to withstand vibrations along the X, Y and Z axes and to avoid interactions with other spacecraft components.

An out-of-this-world student experience

In selecting students for the VISIONS project, the faculty guiding the project—Christopher Edwards, associate professor of planetary science, Michael Shafer, associate professor of mechanical engineering, Christopher Haberle, assistant research professor of astronomy and planetary science, and David Trilling, chair of the Department of Astronomy and Planetary Science—knew they would need individuals from a variety of disciplines. They distributed flyers throughout campus asking interested students to indicate their majors and why they were interested in the project.

“Every student who filled out the survey was invited to participate, and most did participate in the end, at various levels,” Trilling said.

The group met as a class each week for a status and task definition meeting. Sub-teams met separately outside of class to work on their specific areas. The project’s faculty managers also met weekly to ensure everything was progressing according to their timeline.

“These are exceptionally challenging projects,” Edwards said. “Whether it was figuring out the mechanism to secure a tiny electronics board, transferring heat from that board to the instrument chassis in an environment where you can’t use fans or mounting the optics and sensors in a way that will survive launch, the students had to deal with it all.”

Edwards noted that this type of project experience is rare for students. While some have opportunities to complete a subset of a full program in capstone classes, the chance to gain hands-on space-flight experience testing to NASA standards from scratch is rare. The process of developing the concept, designing and analyzing the performance of the hardware, assembling the components and testing them in relevant environments is something only possible at a few universities throughout the country. Students from this program have gone on to work in highly technical aerospace industries including Katalyst Space Technologies in Flagstaff.

A vision of the future

Now that the two VISIONS cameras being sent on the Mars mission have been delivered to Rocket Lab and mounted on the spacecraft, they will go through spacecraft level testing before being cleared for launch. Then in late September or early October, the EscaPADE spacecraft will be launched onboard the Blue Origin New Glenn rocket. The cameras will travel a few hundred million miles over the course of six to nine months to reach Mars.

Once the spacecraft are in orbit around the planet, VISIONS will begin collecting data, acquiring a minimum of one pair of images per orbit. Using thumbnails transmitted back to Earth by NASA’s deep space network, the team will then choose which full-sized images to downlink.

During the months the spacecraft are making their way to Mars, the VISIONS faculty plan to recruit a new cohort of students for the project’s data processing and distribution phase. These students will be tasked with creating a website for archiving the data collected, analyzing and interpreting data, finalizing the instrument’s calibration and evaluating its performance.

“For the operations and analysis phase of the project, we plan to recruit students who have a strong background in computing and data analysis as well as science,” Haberle said. “It’s going to be an exciting time operating an instrument around another planet and analyzing the data that are returned.”

Jessica Clark | NAU Communications

jessica.clark@nau.edu